“One & Done” Capabilities

With over four decades of experience in the precision machining industry, Lincoln Tool & Machine Corp. continues to maintain and improve its tradition of excellence in machined components and assemblies. Established in 1980 by James Ferrecchia, and now with son, Scott, and his wife, Lisa, at the helm, Lincoln Tool continues to be family-owned and operated servicing customers from the New England area to the global marketplace.

Our highly skilled machinists follow each project from design through completion. By working closely with our technical support staff and quality control staff, we are able to develop creative solutions to seemingly impossible machining tasks. The latest in computerized technology and equipment and highly skilled staff assures our customers the highest quality product in a timely fashion.

Lincoln Tool services industries ranging from renewable energy, medical device, robotics, and defense. Dedication to quality combined with proven experience in innovative precision custom machinery guarantees the right solutions to our customers’ machining/assembly needs from the start of the job through final delivery. Check out our manufacturing equipment list here.

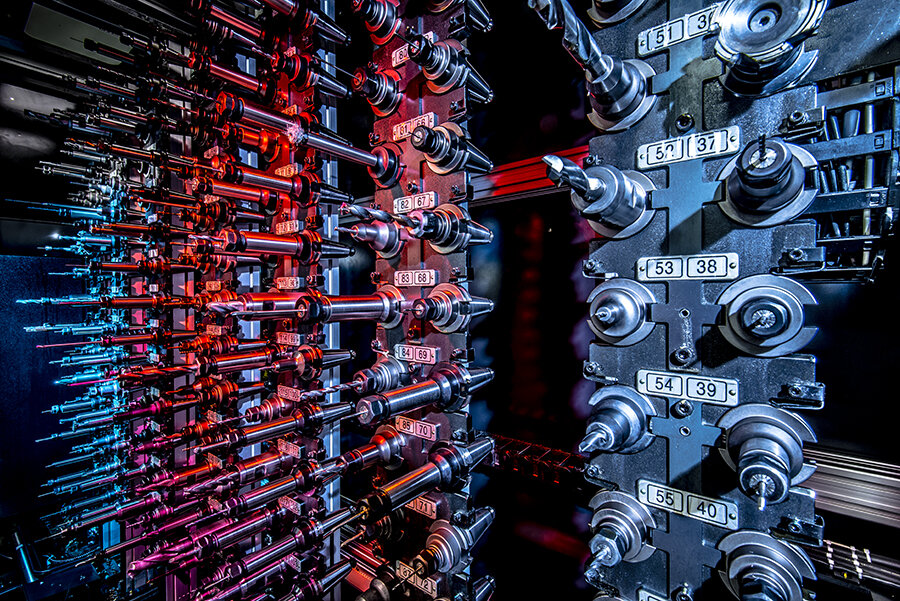

Palletech System

Our Palletech Systems include a simple yet effective scheduler, allowing jobs to be queued and prioritized for seamless operation. Lincoln Tool’s Palletech cells and multitasking systems are an effective strategy for both low-volume and high-volume requirements. Pallets and tombstones with multipart fixtures serve higher production users, saving costs and reducing inventory.

Mazak Integrex

The Mazak Integrex i-150’s automation allows for parts to be built in one set up, increasing production capacity, while saving the customer time and money. The scheduler option in the Integrix allows for jobs to be queued and prioritized for “lights out” unmanned operation.

Methods Practiced

5S

Kaizen

Process flow mapping

Value stream mapping

Pull systems/Kanban/JIT

System and Resource Management

Total quality management

Employee training and skill set enhancement

Continuous process movement

Lean business practicing

Efficient small lot flows resulting in low inventory productivity problems